ELECTRONIC CLEANERS AND LUBRICANTS

CAIG has been developing a wide range of non-polluting products for cleaning all types of electrical or electronic connections for over 40 years.

The DEOXIT range enhances the performance and reliability of all your equipment. It guarantees very long-lasting protection, optimizes conductivity treatment, and significantly improves the quality of your products.

DeoxIT® D-SERIES

Deoxidizer, cleaner, lubricant, and protector

DEOXIT D-Series: Contains very active and fast-acting deoxidizing agents. Guaranteed cleaning with protection and lubrication of contacts to improve the conductivity of all types of metals on connectors or contacts.

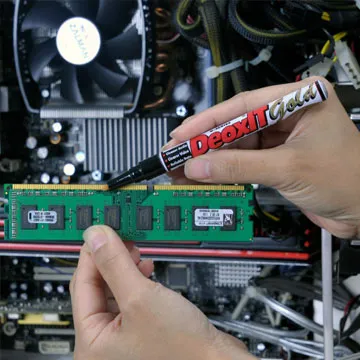

DeoxIT® GOLD-SERIES

Conductivity optimization treatment and protection of metallic surfaces

DEOXIT Gold-Series: It is the only product currently on the market capable of penetrating metalized surfaces and molecular compounds down to the base metals to make them waterproof and protect them.

DeoxIT® FADER SERIES

Optimal lubricant for moving contacts

DEOXIT F-SERIES: It is a precision lubricant for moving contact surfaces (attenuators, switches, potentiometers, and other sliding surface mechanisms).

DeoxIT® Shield Series

Lubricant and protector to optimize metallic electronic contacts.

Recommended after treating contacts/connectors with DeoxIT® D-Series for optimal protection and for new metal surfaces, typically during the manufacturing process.

Deoxidizer, cleaner, lubricant, and protector.

DeoxIT® D-SERIES

DEOXIT D-Series: Contains very active and fast-acting deoxidizing agents. Guaranteed cleaning with protection and lubrication of contacts to improve conductivity of all types of metals on connectors or contacts.

- Improves conductivity

- Cleans and deoxidizes

- Reduces intermittent connections

- Reduces arcing and RF interference

- Reduces wear and abrasion

- Extended temperature range between -35°C and +200°C

Contact surfaces are regularly exposed to dust, smoke, or other solid pollutants in the air. A film can then form and inhibit conductivity. Oxidation is the most common reaction. DEOXIT S-Series removes these deposits. It restores the initial conductivity properties by leaving a thin protective layer on the material.

Why do I need DeoxIT®?

Metal connections in your electronic or electrical devices degrade over time due to oxidation and corrosion. This deterioration leads to performance drops, intermittent failures, data transmission errors, and even complete failures.

DeoxIT® is essential for:

- Restoring connections: It removes oxidation and corrosion, ensuring optimal contact.

- Improve conductivity: DeoxIT® reduces electrical resistance and ensures better signal transmission.

- Long-term protection: It lubricates and leaves a protective layer that prevents the formation of new deposits.

- Prevent failures: By avoiding connection issues, it extends the lifespan of your devices.

In summary, DeoxIT® is the solution to keep your systems performing and reliable.

- Eliminates oxidation and corrosion

- Lubricates and seals connections

- Improves conductivity without the risk of short circuits

- Practically reduces intermittent signals

- Optimizes signal quality

- Increases data transmission speed

- Perfect for fixed parts and those subjected to vibrations

- Reduces wear and abrasion

- Actively drives out moisture and contaminants

Packaging

Spray and Mini Spray

Spray Aérosol (Usually in 57 grams or 163 grams): Ideal for quick and broad applications.

Applicator Pen

Provides maximum precision for small connections or components .

Tube or Syringe

Used for smaller quantities, often for specific applications.

Conductivity optimization treatment and protection of metal surfaces

DeoxIT® GOLD-SERIES

DEOXIT Gold-Series: It is the only product currently on the market capable of penetrating metal surfaces and molecular compounds down to the base metals to make them waterproof and protect them. It ensures the maintenance of bonds between similar or dissimilar metals.

- Improves conductivity

- Maintains optimal signal quality

- Ensures sealing and surface protection

- Reduces abrasion and wear phenomena

- Forms a tarnish-resistant protective layer

- Reduces RF noise and intermittent connections

- Extended temperature range between -35°C and +200°C

- DEOXIT Gold-Series has been specially designed to improve conductivity and provide long-lasting protection for gold, precious metals, and their base metals.

- Durable protection lasting between 1 to 10 years on gold, silver, rhodium, copper, nickel...

WHERE TO APPLY

Use on plated connectors, contacts, and metal surfaces for maximum performance and protection.

Recommended for critical applications where low deoxidizing action is needed. If the surface appears clean, it is generally not necessary to first apply the DeoxIT® D-Series treatment. DeoxIT® Gold is designed to dissolve small amounts of oxidation. Apply DeoxIT® Gold after the DeoxIT® D-Series treatment on plated metal surfaces, unless otherwise indicated for DeoxIT® Shield S-Series below. The more critical the connection or part, especially for low current applications, DeoxIT® Gold should be the final step.

- Improves conductivity

- Maintains optimal signal quality

- Reduces wear and abrasion

- Prevents friction/dendrite corrosion

- Forms a protective tarnish-resistant coating

- Stabilizes connections between similar and different metals

- Reduces electrical arcing, radio frequency interference (RFI), and intermittent connections

- For reference, DeoxIT® Gold has a deoxidizing action of about 0.5%.

Packaging

Spray and Mini Spray

Spray Aérosol (Usually in 57 grams or 163 grams): Ideal for quick and broad applications.

Applicator Pen

Provides maximum precision for small connections or components .

Tube or Syringe

Used for smaller quantities, often for specific applications.

Optimal lubricant for moving contacts

DeoxIT® FADER F-SERIES

DEOXIT F-SERIES: it is a precision lubricant for moving contact surfaces (attenuators, switches, potentiometers, and other sliding surface mechanisms)

It restores original lubrication on surfaces where it has been removed due to cleaning with solvents or other aggressive deoxidizers.

- Lubricates attenuators, switches, potentiometers, and other sliding surfaces

- Maintains signal quality at its optimal level

- Reduces wear and abrasion

- Preserves tactile feel

- Formulated for controls made of conductive plastic or carbon-based materials

- Operating temperature range between -25°C and +150°C

Ideal for restoring lubrication. Deoxit F-Series is neither a deoxidizer nor a cleaning product. It is advisable to use it in conjunction with DEOXIT D-Series

APPLICATION EXAMPLES

- Faders, switches, carbon potentiometers, all moving parts plastic against plastic or plastic against metal surface

- Computer equipment

Uses

- Lubrication/protection of plastic to plastic parts (faders)

- Plastic to metal parts (faders, linear guides – dot matrix printers)

- Metal to metal parts (sliding and slow rotating metal parts, locks, bearings)

- Carbon-based controls (potentiometers) and membrane switches (mouse pointers, touch keyboards)

- Damping grease for tactile feel (DeoxIT® FaderGrease)

- Dissolves oxidation and corrosion

- Formulated for conductive plastics and carbon-based controls

- Lubricates faders, switches, potentiometers, and other mechanisms with sliding surfaces

- Maintains optimal signal quality

- Reduces wear and abrasion

- Preserves tactile feel

- Temperature range: -26°C to 150°C

Packaging

Spray and Mini Spray

Spray Aérosol (Usually in 57 grams or 163 grams): Ideal for quick and broad applications.

Syringe

Offers maximum precision for small connections or components.

Tube /Bottle with brush or dropper

Used for smaller quantities, often for specific applications.

Lubricant and Protector to optimize metal electronic contacts

DeoxIT® Shield S-Series

Recommended after treating contacts/connectors with DeoxIT® D-Series for optimal protection and for new metal surfaces, typically during the manufacturing process.

It is also ideal in heavily polluted environments (sulfur, salts, acids, etc.). The DeoxIT® Shield S-Series should be applied to a clean surface – after using DeoxIT® D-Series or another cleaning method.

For reference, DeoxIT® Shield has no deoxidizing action (0%).

TheDeoxIT S-Series Shieldis a product designed to protect electrical or electronic contacts and connections after cleaning. Unlike other formulations that primarily target cleaning and restoration, DeoxIT S-Series acts as a protective barrier, preventing future issues related to oxidation, corrosion, and moisture.

- Long-lasting protection: Forms an ultra-thin film to prevent corrosion and enhance the durability of contacts.

- Moisture and contaminant prevention: Ideal for humid, dusty, or corrosive environments.

- Performance enhancement: Reduces signal loss and minimizes electrical resistance of connections.

- Compatibility: Suitable for already clean and treated metals, such as gold, silver, copper, and alloys.

Where to apply

- Connections in harsh environments

- Batteries, bulbs

- Switches and relays

- Sockets and plugs

- Harnesses, grounding blocks

- RCA, XLR, USB, HDMI, Ethernet, etc. connectors.

- Improves conductivity

- Lubricates and preserves

- Durable in harsh environments

- Reduces intermittent connections

- Works on fixed and mobile contacts and connections

- Stabilizes connections between similar and dissimilar metals

- Reduces electrical arcing and radio frequency interference (RFI)

- Reduces wear and abrasion

- Temperature range: -34 °C (-29 °F) to 210 °C (410 °F)

Packaging

Applicator Pen

Offers maximum precision for small connections or components.

Spray and Mini Spray

Spray Aérosol (Usually in 57 grams or 163 grams): Ideal for quick and broad applications.

Tube /Bottle with brush or dropper

Used for smaller quantities, often for specific applications.