Wear Contacts:

RJ - USB/A - USB/C - 2.0/3.0/3.1 - HDMI ...

Whether in consumer electronics or in the industrial sector, interfaces are present in almost every device. To ensure product reliability, it is essential to subject these connections to various tests during the manufacturing process.

Sustainable Solution for Production Testing

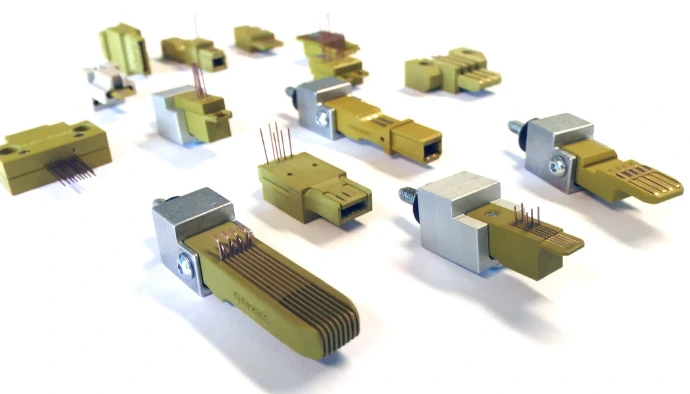

ENGMATEC Wear Contacts

The demand for solutions for testing standard connectors such as USB, RJ-45, or HDMI is significantly increasing, both in the field of ICT and functional testing of printed circuit boards and in cable harness testing. In the automotive sector, there is a growing use of the RJ-45 or USB-C (3.1 and 4.0) connector as the main interface for communication modules.

The Engmatec wear contact is an essential component in production test environments. Designed to ensure reliable and repeated connections, it is ideal for applications requiring high precision and durability.

We offer connectors for the most common types such as RJ, USB, Micro USB, Mini USB, HDMI, eSata, and DisplayPort. Made from high-tech plastic, these connectors are particularly resistant to wear and benefit from an extended lifespan due to the copper contacts integrated into their design.

Unlike a standard USB or RJ-45 connector, a specialized test connector offers the advantage of not locking, having a lifespan exceeding 100,000 cycles, and being particularly resistant to wear. Furthermore, its use prevents overloads or unnecessary damage to the contacts of the tested component.

This design facilitates the replacement of the test connector in case maintenance is needed. These connectors can be easily integrated into test benches and modules. Contact with the component to be tested can be achieved either by the movement of the bench or module, or by integrating the connectors into a pneumatically actuated unit.

Applications:

- Test benches for electronic production

- Functional checks on production lines

- Connectivity tests for complex devices

The Engmatec wear connector is an essential choice for testing in demanding industrial environments, where robustness and precision are indispensable.

The Engmatec wear contact is an essential component in production test environments. Designed to ensure reliable and repeated connections, it is ideal for applications requiring high precision and durability.

We offer connectors for the most common types such as RJ, USB, Micro USB, Mini USB, HDMI, eSata, and DisplayPort. Made from high-tech plastic, these connectors are particularly resistant to wear and benefit from an extended lifespan due to the copper contacts integrated into their design.

Unlike a standard USB or RJ-45 connector, a specialized test connector offers the advantage of not locking, having a lifespan exceeding 100,000 cycles, and being particularly resistant to wear. Furthermore, its use prevents overloads or unnecessary damage to the contacts of the tested component.

This design facilitates the replacement of the test connector in case maintenance is needed. These connectors can be easily integrated into test benches and modules. Contact with the component to be tested can be achieved either by the movement of the bench or module, or by integrating the connectors into a pneumatically actuated unit.

Applications:

- Test benches for electronic production

- Functional checks on production lines

- Connectivity tests for complex devices

The Engmatec wear connector is an essential choice for testing in demanding industrial environments, where robustness and precision are indispensable.

- Proven reliability: Ensures safe and accurate connections, even after many cycles.

- Simplified maintenance: Easy to replace or maintain, minimizing downtime.

- Test optimization: Reduction of errors thanks to a design tailored to industrial needs.

- Lifespan: 100,000 to 200,000 cycles.

- Flexible mounting ensuring self-centering of the connector.

- Connection: Plug & Play system.

- Feature: no locking in the connector.

USB 2.0 / 3.0 / 3.1 and 4.0

HDMI

Ethernet

Displayport

DC, Firewire,...

eSata

A simple solution to TEST your electronic products

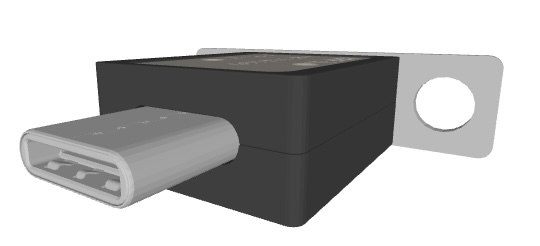

COTELEC Wear Socket

The need for contact solutions for standard connectors such as USB, RJ, or HDMI is growing not only in the field of ICT and functional testing of printed circuit boards but also in cable harness testing. Currently, in the automotive sector, we are witnessing a spread, especially of the RJ-45 socket as the central data interface for communication modules.

Compared to a standard USB or RJ-45 connector, a specific test connector has the advantage of not locking, having a lifespan well above 100,000 cycles, and being very resistant to wear. Furthermore, its use helps avoid overloading or unnecessary damage to the contact elements of a component being tested. The connection of the connector on the test bench side is done very easily and without soldering using the standard connector corresponding to the component being tested (plug and play). This design allows for very easy swapping of the test connector in case of maintenance.

These connectors can be very easily mounted in test benches and modules. The contact with the component being tested can thus be made either through the travel of the bench or module or by integrating the connectors into a pneumatically controlled unit.

- Transmission via a standard connector

- Easy contact with the component being tested (Front view)

- Easy connection to the test system with a standard USB cable (Rear view)

- More than 100,000 cycles

Choose the test connector and the corresponding support based on your needs.

- For example, for USB:

Align the bottom plane of the test connector with the bottom plane of the component to be tested:

USB 2.0 / 3.0 / 3.1 and 4.0

HDMI

Ethernet

Contact-us