ICT Test Fixtures :

In-situ

In-situ test interfaces are designed to test electronic components directly on the board or module without requiring disassembly. This type of testing allows for the analysis of circuit performance in their real environment, ensuring accurate results that reflect actual usage conditions.

Make an Appointment Documentation Request a Quote

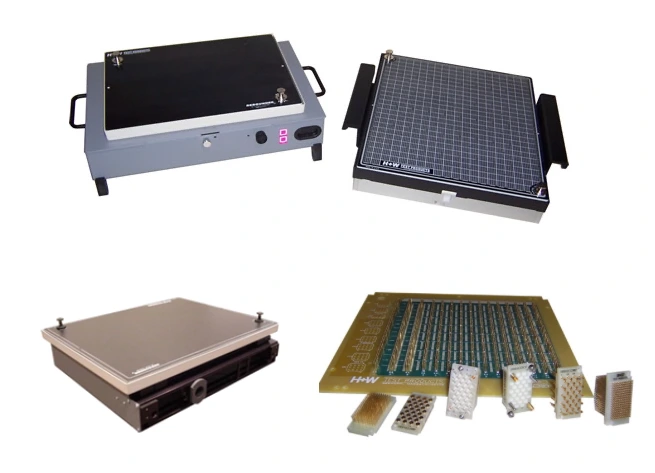

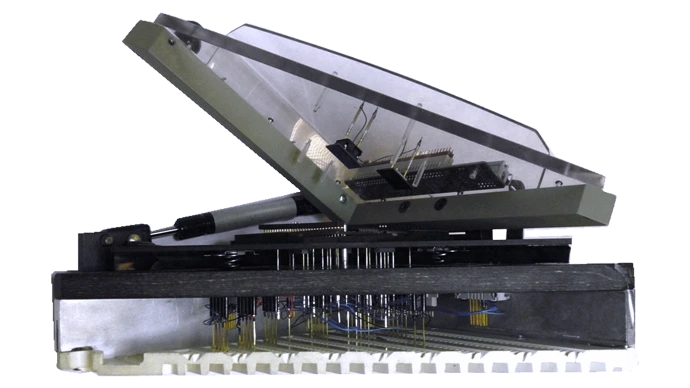

Vacuum Manual

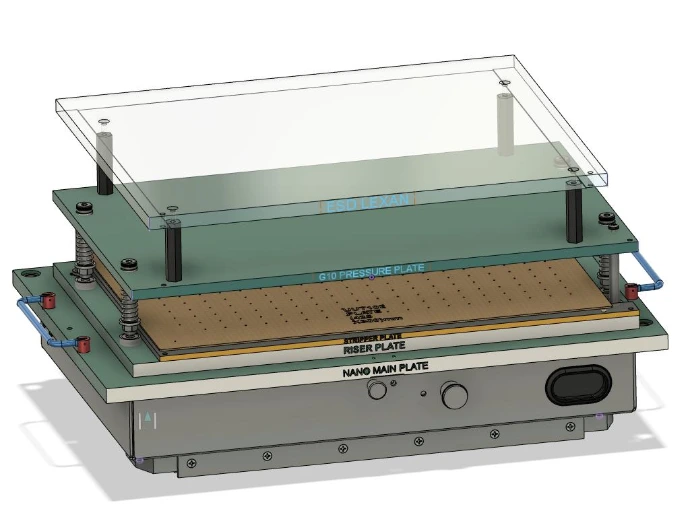

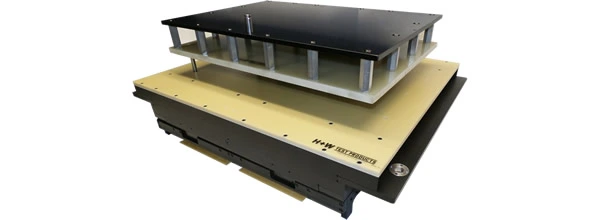

In-Situ Fixtures: Offline

Offline In-Situ test fixtures are devices designed to test printed circuit boards (PCBs) and electronic assemblies independently, outside of the main production line. They allow for detailed, precise, and controlled analysis, often in a dedicated environment where technicians can intervene directly. Available on all test platforms such as KEYSIGHT / TERADYNE-GENRAD / SPEA ...

Main Objective

- Detection of electrical and mechanical defects: Enables the rapid identification of errors such as defective soldering, short circuits, missing or misplaced components.

- Validation offline: Reduces disruptions on the main production line by isolating complex or prolonged tests.

- Operational Flexibility: Adaptable for one-off tests or limited series.

Typical Applications

- Final Quality Control: Performance verification before shipping.

- Prototype Validation: Rigorous testing before mass production.

- Failure Analysis: In-depth diagnostics of defective PCBs.

- Small Production Runs: Quick adaptation for limited batches.

Offline In-Situ test interfaces ensure maximum accuracy in inspection and diagnostics while allowing for better resource management and production flow. They are an ideal solution for industrial environments where quality and flexibility are priorities.

- Testing Flexibility: Tests are conducted offline, providing more time to diagnose and analyze components without disrupting the production flow.

- High Precision: These interfaces allow for thorough testing, detecting complex defects that may go unnoticed in faster inline tests.

- Enhanced Quality Control: Ideal for products requiring extensive validation, they ensure optimal quality by identifying issues before final integration.

- Multi-Level Compatibility:Testing at one or multiple contact levels to ensure optimal coverage. Ability to use bi-level configurations for more complex analyses.

- Integrated Diagnostic Equipment:Integration of advanced diagnostic software. Real-time monitoring of critical test points.

Offline in-situ interfaces are essential for sectors requiring high reliability, such as automotive, aerospace, and medical, where the quality and safety of components are paramount.

- Isolation of Complex Issues: In-depth testing can be performed without disrupting the production line.

- Easier Maintenance: Simplified access for repairs and manual adjustments.

- Reduction of Downtime: Fewer interruptions on the main production line.

- Increased Flexibility: Suitable for custom productions or prototypes.

Compatible with Testers

KEYSIGHT

HP3070 - i3070 ...

TERADYNE - GENRAD

GR2270 - GR228X - TestStation, LH ...

SPEA

3030-X - ...

For Automatic Handler

In-Situ Fixtures:

Inline

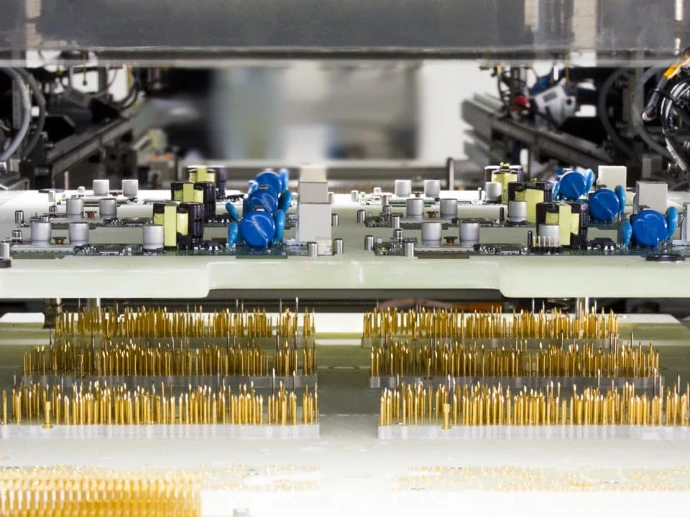

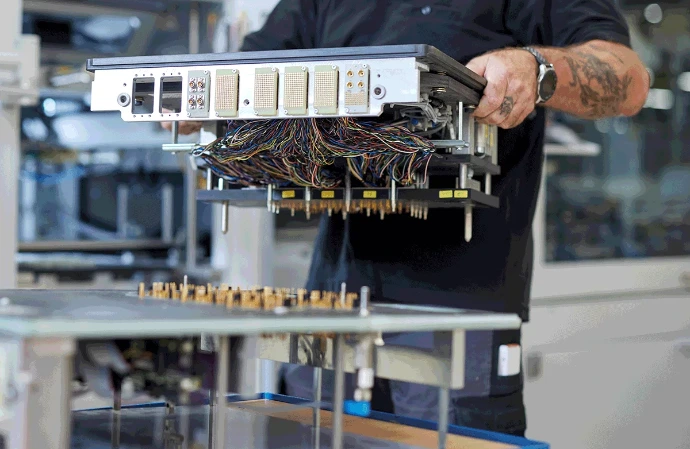

Inline in-situ ATE (Automatic Test Equipment) testing fixtures allow for the testing of electronic components directly on the production line, integrated into an automated testing system. These interfaces enable quick and accurate verification of boards and modules without interrupting the production flow.

Inline in-situ ATE testing interfaces are ideal for industries where speed, accuracy, and automation are essential, such as consumer electronics, automotive, and semiconductors.

What is an In-Situ ATE?

- In-Situ means "on site" or "directly on the circuit."

- ATE (Automated Test Equipment) refers to automated systems used to test and validate electronic components.

An In-Situ ATE allows for direct testing of a printed circuit board or components without removing them from their functional environment.

Operation of In-Situ ATE Interfaces

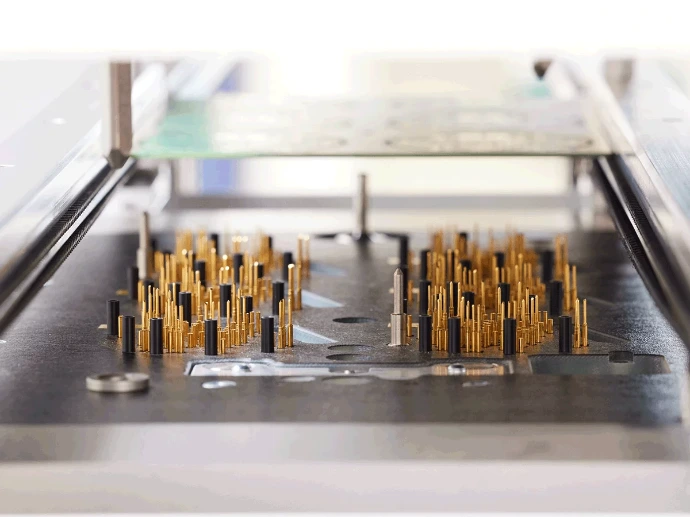

- Access to test points: Probes or special connectors allow access to electrical signals on the PCB.

- Test automation: Tests are automated via ATE software, ensuring repeatability and accuracy of measurements.

- Data acquisition: Electrical signals are captured and analyzed to detect defects or performance variations.

- Diagnosis and reporting: Detected anomalies are reported with detailed reports.

Types of In-Situ ATE Interfaces

Bed-of-Nails:

- Used to test multiple points simultaneously on a PCB.

- Ideal for large production runs.

Custom Connectors:

- Designed specifically for certain boards or components.

Common Applications

- Electronics industry: Manufacturing and assembly of PCBs.

- Aerospace and defense: Rigorous testing of critical components.

- Automotive: Validation of embedded electronic systems.

- Telecommunications: Maintenance and troubleshooting of network equipment.

In-Situ ATE interfaces play a crucial role in quality control and performance assurance of electronic systems, providing automated, precise solutions tailored to modern industrial needs.

- Rapid defect detection: Allows for the identification of defective components early in the manufacturing process.

- Increased efficiency: Automation of tests, reducing time and costs.

- Flexibility: Adaptation to different types of boards and electronic configurations.

- Measurement accuracy: Minimization of human errors.

Compatible with Testers

KEYSIGHT

i3070 - i7090- E9988X ...

TERADYNE - GENRAD

TestStation

SPEA

T300